Explosions from combustible dust have been an issue in manufacturing for hundreds of years, but it wasn’t until OSHA began investigating industrial dust explosions that the common causes of these explosions were discovered. The creation of the Combustible Dust National Emphasis Program created a place for all of the data about dust explosions to be compiled and analyzed so that we can learn from these disasters.

Explosions from combustible dust have been an issue in manufacturing for hundreds of years, but it wasn’t until OSHA began investigating industrial dust explosions that the common causes of these explosions were discovered. The creation of the Combustible Dust National Emphasis Program created a place for all of the data about dust explosions to be compiled and analyzed so that we can learn from these disasters.

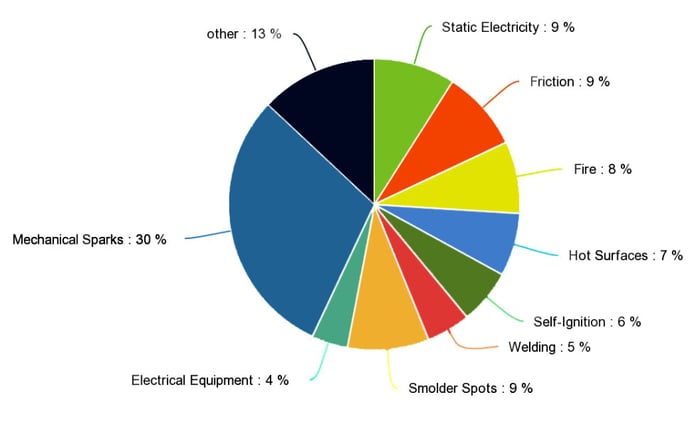

One piece of valuable information is what percent different ignition sources contributed to an industrial dust explosion. Surprisingly, fire only caused 8% of these explosions, which was less that static electricity, which caused 9%. The largest cause of dust explosions was from mechanical sparks, at 30%. One issue that many people aren’t aware of is that many dusts can self-ignite under the right conditions, and this effect caused 6% of all the explosions.

What does this graph of ignition sources tell us, and what can we take from it to prevent a dust explosion?

Many of these sources are preventable with routine maintenance and fire safety procedures. Keeping machinery properly maintained and cleaned will prevent it from sparking during operation, which is the largest cause of explosions. Just think- if one of your machines isn’t greased properly it could spark and cause an explosion that destroys your entire factory!

Other fixable problem areas include friction, static electricity, and electrical equipment. Steps can be taken to ease frictions points, dissipate static electricity, and ground electrical equipment, but sometimes the risk from these ignition sources isn’t able to be completely prevented. In these cases it is essential that the combustible dust be removed from the area, so that even if one of these ignition sources is created it doesn’t have anything larger to ignite.

When there is welding or hot surfaces the ignition source can’t be prevented, and in these cases a safe zone needs to be created and maintained around the ignition source. This means that no flammable or explosive materials can be inside this area and safety measures need to be taken to ensure safety while the ignition source is present.

Smolder spots and self-ignition can be an issue for dusts that range from chemicals to common wood dust. If the present dust is known to cause smolder spots or self-ignite it is important to take steps to prevent it from igniting. Some chemicals require being submerged in water or other liquids, or some dusts can only self-ignite when they become dry. It’s important to know the difference though- adding water to wood dust will help prevent an explosion, but adding it to magnesium dust will cause it to ignite!